Mold Development and Component Integration

Through one-stop services—including sheet metal stamping and the integration of internal to external metal components—we provide high value-added manufacturing solutions to our clients.

Production Process

Stamping processing

The stamping process transforms raw metal materials into precision parts required for automotive, electronics, and industrial applications. High-precision stamping equipment and die design, combined with interconnected robotic arms, improves production efficiency and enables large-scale production.

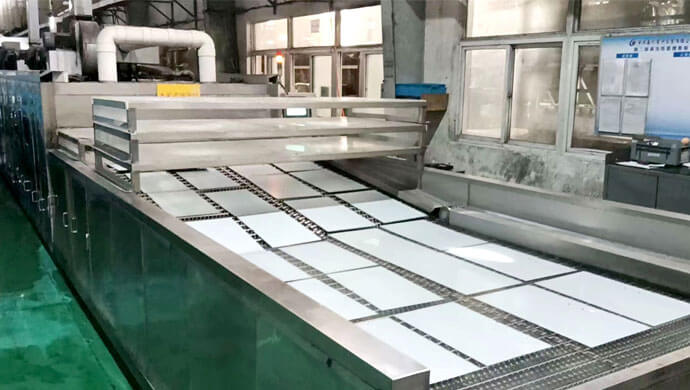

Ultrasonic cleaning

Ultrasonic cleaning ensures that stamped parts are free of oil, dirt, and debris during the sheet metal stamping process. It forms a protective film on the workpiece surface, thereby improving surface quality and durability and delaying oxidation of the metal surface.

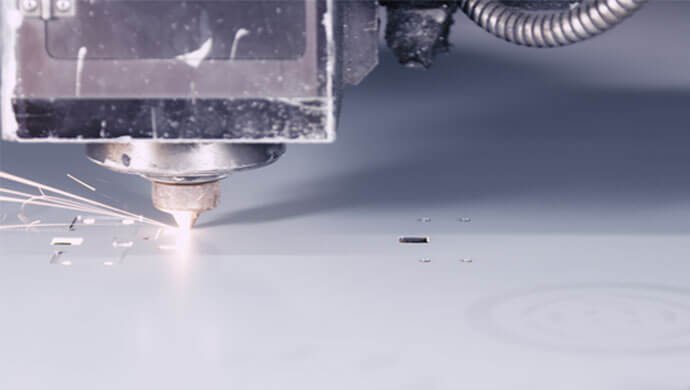

CNC (Computer Numerical Control) machining

CNC machining is often integrated into the sheet metal stamping process, enhancing precision and achieving complex geometries for high-performance components.

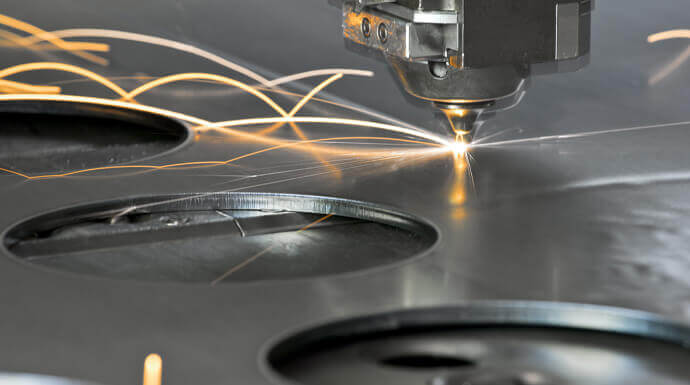

Laser cutting and sheet metal processing

Through laser cutting and bending machine forming, we provide customers with quick and flexible sample production and small batch manufacturing.

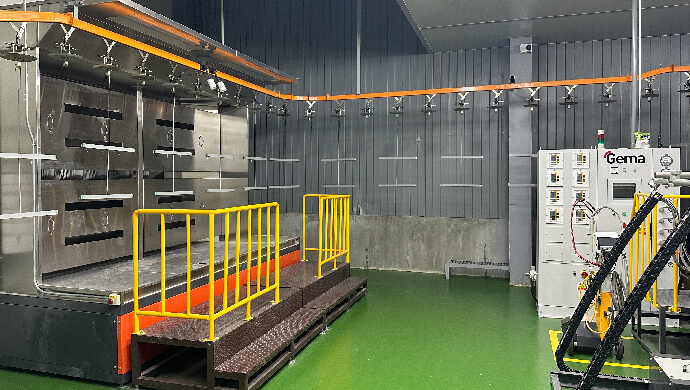

Baking paint

With capabilities for both powder coating and liquid coating, we offer a wide range of color and surface roughness options, achieving both aesthetic appeal and protection for the workpieces.

Anodizing

Through dyeing for oxidation resistance treatment, combined with pre-processing methods such as sandblasting or brushing, we not only enhance the appearance's diversity but also preserve the original metallic texture of the workpiece.

Assembly

Equipped with system testing capabilities, we provide customers with integration and assembly services.